Restoration & Repair: Beogram 4000/6000 Repair and Restoration

This page discusses a number of issues I fixed in Beogram 4000 series turntables. Visit my YouTube Beogram 400x playlist for direct in-sequence access to the videos.

Remote Control System for Beogram 4002/5513 models and 4004 models

|

The keypad surfaces of the 400x series turntables are fairly fragile, and frequent use of the switches degrades the surface. 'Smudges' on the more frequently used pads are the consequence. Hence, a remote control system was designed that allows the use of a Apple remote to fully control all turntable functions, thus reducing the need for using the keypad. The remote system also implements an improved (dynamic) cueing function, which enables a more natural and fast positioning of the tone arm similar to the cueing function offered by the Beogram 8000/8002 models.

The remote system is based on a microcontroller that takes over all keypad functions, while fully preserving the original keypad functionality. The installation is plug-and-play and completely reversible, and no permanent modifications to the turntable are required. Once installed, the only indication of the presence of the remote system is the small infrared receiver that protrudes from underneath the cabinet. More information can be found in this blog entry, and in the YouTube video posted to the right. |

|

|

The tracking sensor uses an incandescent light bulb, which frequently expires due to old age or due to vibrations during transport of the Beogram. This light bulb is not available anymore. The linked blog entry and the YouTube video to the right discuss the replacement of the sensor bulb with a drop-in ready SMD LED based 3D printed assembly. The video also shows how to adjust the tracking mechanism after the exchange. The featured LED assembly is available upon request.

|

|

The speed selector of the Beogram 400x uses incandescent light bulbs to illuminate the speed adjustment scales. These light bulbs frequently burn out. LED replacements can be fitted easily. However, in order to achieve a proper incansecent appearance red/green dual emitter LEDs need to be used to ensure a red reflection of the scale indicators. The linked blog entry and the YouTube video on the right discuss this process.

|

|

|

The detector arm uses a hard-to-find light bulb that is used to detect the presence of a record. This light bulb can be replaced with a 3 mm LED if the circuit is modified appropriately. The linked blog entry and YouTube video on the right discuss this process. The video also discusses how the detecting circuit works.

|

|

The transport lock allows to fasten the freely suspended chassis of the Beogram 4000 series turntables during transport. In locked down condition the chassis is cushioned with elastomer bushings against the enclosure to protect the mechanism from high acceleration forces. These bushings degrade over time, and many Beograms have lost them partially or entirely. The linked blog entry and the YouTube video on the right discuss the replacement of the bushings with 3D printed parts. The 3D printed parts are available upon request.

|

|

|

Precise adjustment of the tracking force (or rather weight) is the main prerequisite to get the most out of your cartridge, as well as of your records. Too heavy tracking weights damage stylus and record, while too light weights lead to distortion and poor music reproduction. The linked blog entry and the YouTube video on the right discuss the adjustment process and how to use the tracking force gauge that comes with B&O cartridges.

|

|

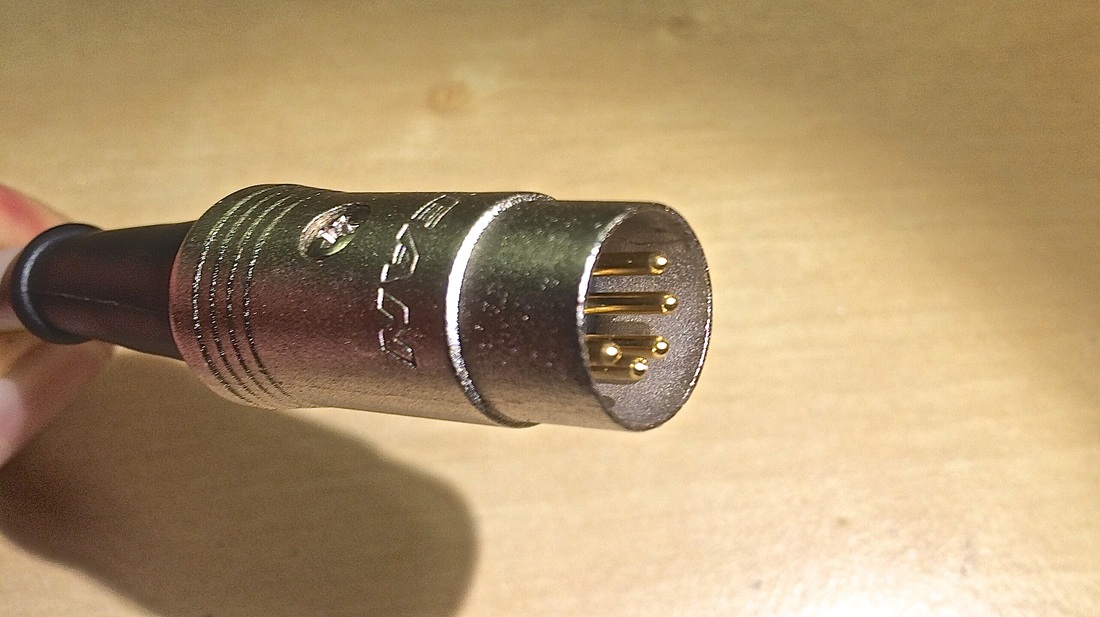

Old age and corrosion often makes it desirable to replace the DIN 5 plug that is standard on the Beogram 4000 series turn tables. Modern plugs also are available with gold plated contacts, which takes the guess work out of forming proper low resistance signal paths between the cartridge and the pre-amplifier. The linked blog entry discusses the plug replacement, as well as the signal path between the cartridge and the amplifier.

|

Newly installed Neutrik AG plug with gold plated pins.

|

|

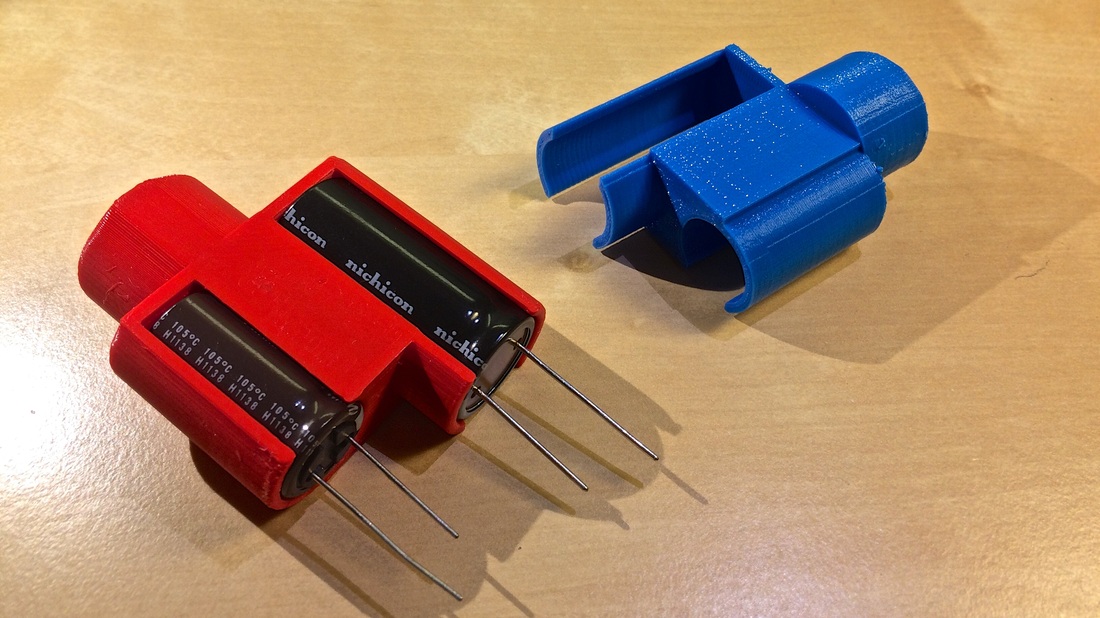

Some Beogram 4002 (5513) models have a separate power supply for an optional preamplifier/CD4 decoder board. This power supply is stabilized with a 1000uF capacitor that is originally integrated with the main 4000uF reservoir capacitor. These two-in-one capacitors are not available anymore, i.e. two separate capacitors need to be used for their replacement. The linked blog entry discusses the replacement process utilizing a 3D printed adapter that houses the new capacitors.

|